What is a Dry Box / Dry Cabinet?

Desiccant dry cabinets, or dry boxes, are reasonably new to the North American marketplace, but have been used regularly in more humid regions of the globe such as Asia for many years. To assist you in becoming familiar with some of the issues and questions surrounding desiccant dry cabinets (AKA; dry boxes, desiccators, dehumidification cabinets) we’ve assembled the following ‘FAQ’ page of information for you to review. If you have questions regarding specific models, a custom project, or anything else that is not covered here, or if you would like to discuss the possibility of in house trial, please contact us.

How does a dry box work?

A dry cabinet is an enclosure with a supply of desiccant which maintains an internal environment of 1-50% RH. Desiccant dry cabinets are also called; desiccators, dry boxes, dehumidifying cabinets, & ultra low humidity storage cabinets. Desiccant itself is defined as; A substance that has a high affinity for water and is used as a drying agent – From Latin siccus. Commercially, desiccant materials are supplied as; Montmorillonite Clay, Silica Gel, Indicating Silica Gel, Molecular Sieve, Calcium Oxide, Calcium Sulfate, and Zeolite, just to name a few.

Desiccants naturally ‘traps’ airborne moisture particles as they come into close proximity. When an amount of desiccant is placed within an enclosure it absorbs as much moisture as it can, making that enclosure dryer. When an item that contains moisture, even trace amounts, is placed within a low humidity (‘dry’) environment, the moisture will slowly be released from the item into that ‘dry’ environment. The reality is that the cabinet’s RH level (relative humidity) is so low that the air inside will act as a magnet to the trapped moisture inside your items, and it will draw it out, into the air within the cabinet. It will continue to do this until there is some kind of equilibrium reached between the moisture level still trapped in the item and moisture level of the cabinet or until the desiccant is saturated.

Equilibrium or desiccant saturation however should never be reached as all desiccant dry cabinets have some manual or automatic procedure for voiding the desiccant of the moisture that it has collected from the cabinet interior and from the items stored within. Once the interior of the cabinet is exposed to refreshed desiccant the dehumidifying, drying, or protective process is continued, and the environment inside the cabinet is maintained.

Typical applications include the prevention and protection against all types of oxidation (rust), the prevention of the growth of fungus on optics, the dry preservation of lab materials and samples as well as the protection of MSD’s (moisture sensitive devices) as per IPC/JEDEC J-STD-033 & J-STD-020 within the electronics industry.

BUT… Not all dry cabinets are created equal…

About desiccant dry cabinets / dry boxes:

- What should be stored in a dry desiccant cabinet?

- What are the defects that I could experience related to moisture contamination of MSD’s?

- How can I tell if I have MSD related defects occurring on my floor?

- Will storing my components in an XDry Dry Cabinet satisfy IPC JEDEC J-STD-033?

- What is desiccant, and how does it work?

- How do your Dry Cabinet desiccant dryers function?

- What is RH recovery time in your dry boxes?

- Do your Dry Cabinets use heat to dissipate moisture?

- Do the Dry Cabinets require Nitrogen?

- What are the benefits over Nitrogen of a Desiccant dry cabinet?

- What are the benefits of Desiccant Dry Cabinets over Moisture Barrier Bags (MBB’s)?

- What are the benefits of Desiccant Dry Cabinets over baking?

- Are the Dry Cabinets / dry boxes clean room safe?

- Are your Desiccant Dry Cabinets ESD safe?

- What is the benefit of your Dry Cabinets / dry box ‘Auto-on’ feature?

- Will the RH level remain constant in an your Dry Cabinet?

- What happens to my Cabinet if the power goes off?

- Do the number of doors represent the number of storage areas in the dry cabinets?

- Can I change the configuration of the Cabinet’s interior?

- Can I monitor my Desiccant Dry Cabinets over a network?

- Does the desiccant require replacing?

- Do your Dry Cabinets / dry boxes require any maintenance?

- Do these Dry Cabinets / Dry Boxes require calibration?

- Where can I get replacement parts and service for my Desiccator Dry Cabinet?

- Who is responsible for shipping the Desiccator Dry Cabinets?

- Do you provide customer service and technical support over the phone?

- Can your desiccator dry cabinets be upgraded?

- Are the dry cabinets designed with redundancy?

- Where are your warehouses located?

- Do you sell your desiccator dry cabinets through distributors?

- How do your dry cabinets remain so dry without the use of nitrogen?

- Is it difficult to set up or install an XDry cabinet

- Can your dry cabinets be fitted with reel racking or reel storage type systems?

- How do your dry cabinets work?

What should be stored in a dry desiccant cabinet?

- Any component classified as an MSD (Moisture sensitive device), particularly devices classified as level 4-5a. These devices are most susceptible to moisture related defects.

- Partially populated double sided boards. While waiting to re-enter production to have 2nd side assembly done, components begin to absorb moisture that could do harm once the PCB is introduced back to the reflow oven.

What are the defects that I could experience related to moisture contamination of MSD’s?

Bond damage, wire necking

Bond lifting, die lifting

Thin film cracking, cratering beneath the bonds

Corrosion due to ionic contaminants

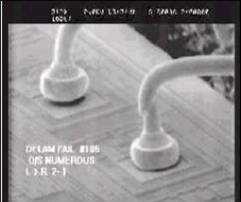

Popcorning

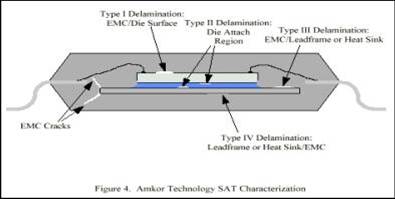

Increase in thermal resistance due to delamination

How can I tell if I have MSD related defects occurring on my floor?

- Initially you may not see any signs of some of the defects listed above. Others defects such as cracking may be visible to the eye, and ‘Popcorning’ occurring may actually be heard coming from inside your oven in severe cases. Still, it’s very difficult to detect these defects, even standard ICT may show no abnormalities If you are interested in determining weather your process may be susceptible to moisture related damage you could run the following test;

- Allow a tray of MSD’s to flow through your process as they normally would while being assembled (including all dwell times and reflow), at the end of the process send the MSD’s to an independent lab for scanning acoustic microscopy, or cross-sectioning. If defects are evident in the results then you can be sure that you would realize savings and reliability with the implementation of an MSD control program.

Will storing my components in a Dry Cabinets satisfy IPC JEDEC J-STD-033?

- No is the short answer. Arbitrarily storing moisture-sensitive devices (MSDs) in a desiccant cabinet, dry box, nitrogen cabinet, or other dehumidification device does not, on its own, satisfy the requirements of IPC J-STD-033. This alone will not “stop the clock” on MSD floor life. However, the proper implementation and use of a desiccant dry cabinet capable of maintaining less than 5% relative humidity (such as our Dry Cabinet) – with calculated storage durations based on floor exposure time – is a crucial component of an effective MSD control program.

What is desiccant, and how does it work?

- Desiccant refers to a substance that strongly attracts water and is commonly used to dry things out. The term comes from the Latin word “siccus,” meaning dry. There are many types of desiccants, including Montmorillonite Clay, Silica Gel, Indicating Silica Gel, Molecular Sieve, Calcium Oxide, Calcium Sulfate, and Zeolite. High-quality desiccants can be recycled or refreshed easily, allowing them to regain their drying power.

How do the Dry Cabinets’ desiccant dryers function?

Depending on the size and type of model in question, up to three high performance dehumidification units may be installed. These units are simple and reliable and are the result of many years of research.

This diagram outlines the basic operation of the dryer units. Each unit contains a specialized desiccant that is exposed to the cabinet interior, absorbing moisture over a period of time. Depending on the user’s settings, the dryers will periodically seal themselves off from the cabinet to recycle and refresh the desiccant. This refreshing process involves heating the desiccant to release the trapped moisture as vapor, which then escapes through vents at the back of the cabinet. Once refreshed, the unit seals off the exterior venting and reopens to the interior, ready to continue dehumidifying. An electronic control system ensures the dryer units operate in sync, providing continuous drying power.

What is the Recovery Time of a Dessicator Dry Cabinet?

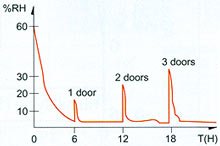

This may be the single most important issue, after Min RH level. Recovery time refers to the time required for the cabinet to reduce the RH level back to <5% RH after the door has been opened and closed.

All of our Dry Cabinets are equipped with our ‘Auto-on’ feature which activates a fan inside the dehumidification units, causing air movement within the cabinet and allowing the newly introduced moisture to be captured before it can begin to degrade the parts already in storage.

This graph illustrates how our Dry Cabinets recover after 1, 2 and then 3 doors are open. This approach provides excellent recovery time, certainly better than the ‘static’ approach used by some of our competitors. In situations where the opening of the doors is exceedingly frequent, and plumbing permits, an optional Nitrogen purge may be installed. This purge would be activated upon the door closing and would continue for a 10-15 minute period (depending on set parameters) allowing the quick voiding of any ambient moisture introduced into the cabinet. This method of recovery will utilize approximately 1/20-1/100 the consumption of a standard nitrogen storage cabinet of the same size.

Do the Dry Cabinets use heat to dissipate moisture?

- De-humidification of the cabinet interior is carried out by desiccant alone, with no cabinet heat involved. Optional cabinet heaters are available as an option.

Do these Dry Cabinets require nitrogen?

- These desiccant dry box storage products do not require nitrogen to maintain the RH levels indicated within the specifications. However for applications that require extreme frequency of door openings and where plumbing permits an optional nitrogen purge may be installed.

What are the benefits of Desiccant dry cabinets over Nitrogen?

- Desiccant cabinets have lower running cost. N2 is void of all oxygen, it is unable to absorb O2 and as a result it is a less effective than desiccant when used as a drying agent. It is typically used under positive pressure to continually displace the oxygen within the cabinet.

- Desiccant cabinets are portable with casters, and do not require plumbing, so they can be moved to a new location whenever required.

- Desiccant cabinets will maintain their internal environment for extended periods (10-+24 Hrs) during power down situations, continuing to protect your components.

- Nitrogen cabinets use a constant positive pressure flow to void the cabinets of all O2; this nitrogen flows out into the production facility, reducing the oxygen density in the area, potentially causing discomfort to staff.

What are the benefits of Desiccant Dry Cabinets over Moisture Barrier Bags (MBB’s)?

- SAVE LABOUR – Trays and reels can be placed directly into cabinet without having to be placed into MBB’s (moisture barrier bags).

- SAVE COST – Less desiccant (i.e. indicating silica gel), and MBB’s required.

- MORE SECURE – no need to be concerned with:

- calculations to determine the correct amount of desiccant,

- the quality and remaining absorbency of the desiccant, and potential mis-sealing,

- possibility punctures of the bags themselves.

What are the benefits of Desiccant Dry Cabinets over baking?

- COST EFFECTIVE – less costly than baking; with a monthly power consumption of only 40.4 kW it’s considerably less expensive than long duration bake cycles.

- MORE EFFICIENT – components are being dehumidified while they sit in inventory, always ready for the next run.

- MORE CONVENIENT – operators will be more inclined to place components into cabinets rather than taking the time to re-bag, especially for short duration exposures.

- SPACE SAVING – smaller outside dimensions than that of comparable burn in cabinets as a result of insulation, wiring, etc.

- BETTER QUALITY – baking SMD packages may cause oxidation or intermetallic growths to form, which can reduce solderability. Component carriers may cause out gassing during baking, again, effecting the solderability.

- LESS CONCERN – standards suggest when baking between 90-125 deg C. a max time of 48 hours be observed, then deviations should be requested. With desiccant cabinet storage there is no maximum to observe. Less handling; there is no need to transfer components from their standard packaging to high temp carriers in preparation for the bake, possibly introducing physical damage to the component itself.

Are XDry Dry Cabinets clean room safe?

- The XDry Clean is designed to be a mobile class 100 clean room. With it’s powerful air purification system, HEPA filters, non dust generating stainless steel shelves, and dust free urethane casters it’s a practical and quick moisture proof storage solution for your clean room requirements.

Are XDry Dry Cabinets ESD safe?

- All of our Dry Cabinets are ESD safe. Standard features include; Stainless steel shelves, conductive glass, conductive paint on all cabinet surfaces, and 1MΩ earth lead

What is the benefit of XDry Dry Cabinet ‘Auto-on’ feature?

- The Dry Cabinet auto-on feature provides an opportunity after each door opening to capture the newly introduced moisture before it has a chance to settle. The movement of the air (and its entrapped moisture) within the cabinet provides more opportunity for those moisture particles to pass within the desiccants reach.

Will the RH level remain constant within an XDry Dry Cabinet?

- Studies have shown that our XDry technology, as designed into our dehumidification unit allows the cabinet to remain at the operator set RH without any difficulties.

What happens to my XDry Dry Cabinet if the power goes off?

- Our Cabinets are designed and manufactured to be able to maintain an environment of <5% RH for a period of 10 days, and <10% RH for a period of approximately x 20 days if the cabinets remain closed and no new moisture is introduced.

Does the number of doors represent the number of storage areas in an XDry Dry Cabinet?

- No, there are a variety of models, with a variety if door configurations. The interior of the cabinet is one environment. There is benefit however from a higher number of doors; there is less of an exchange of atmosphere when a smaller door is opened and closed.

Can I change the configuration of the Dry Cabinet interior?

- The Dry Cabinet auto-on feature provides an opportunity after each door opening to capture the newly introduced moisture before it has a chance to settle. The movement of the air (and its entrapped moisture) within the cabinet provides more opportunity for those moisture particles to pass within the desiccants reach.

Can I monitor my Dry Cabinet(s) / dry box over a network?

- No.

Does the desiccant require replacing?

- No, the desiccant is extremely well suited to the task and should perform well under normal operating conditions for 10 years or more without replacement..

Do these Dry Cabinets require any maintenance?

- Our dry cabinets are 100% maintenance-free, meaning that there is no user intervention required for the XDry cabinets to continue delivering ultra-low humidity environments around-the-clock.

Do your Dry Cabinets require calibration?

- Although XDry cabinets do not require calibration, there is a procedure that allows a humidity standard to be used and the display offset to be registered. The sensors used inside our dry cabinets have a ±1.5% Rh tolerance.

Where can I get replacement parts and service for my XDry Cabinet?

- We will be happy to respond to all of your service and spare parts requirements .

Who is responsible for shipping?

- Shipping within the USA is included in the cost of all of our products.

Do you provide customer service and technical support over the phone?

- We provide technical support over the phone, toll free at 1-833-265-9440 from 7 AM Eastern to 6 PM Eastern.

Can XDry cabinets be upgraded?

- XDry cabinets can be upgraded with additional dryers, nitrogen purge systems, and other features depending on the original configuration. Please contact the our sales team for further information.

Are your dry cabinets designed with redundancy?

- The mid- and large-size dry cabinets are designed with redundant systems to ensure that moisture-sensitive devices stay safe for years to come, even in the event of a system failure.

Where are your warehouses located?

- XDry cabinets as well as spare parts and options are stored at our facilities in Texas, USA.

Do you sell through distributors?

- XDry cabinets can be purchased through distribution channels, contact our sales team for additional information.

How do XDry cabinets remain so dry without the use of nitrogen?

- Our dry cabinets use a highly absorbent desiccant that is capable of capturing trace amounts of moisture, providing a constant less than 1% Rh environment.

Is it difficult to set up or install an XDry cabinet?

- Our dry cabinets require 110 V and nothing more. The moisture that is captured is released back into the environment as minimal amounts of water vapor. No special requirements from facilities needs to be supplied.

Can XDry cabinets be fitted with reel racking or reel storage type systems?

- The mid- to large-size dry cabinets can be optionally fitted with fixed or sliding reel racks with complete adjustability for reel thickness.

How do XDry cabinets work?

- These cabinets are designed with an industrial desiccant dryer system that absorbs all of the moisture in the environment and causes moisture that is trapped inside of materials to be leached out, drying its contents gently. Once the user setpoint humidity within the environment is reached, the desiccating stops. The dryers use preset intervals for a recycling process that refreshes the desiccant back to its original full-strength absorption capability.

USA Sales & Support:

214-296-4868

Worldwide Sales & Support:

+1-833-265-9440

Bond damage, wire necking

Bond damage, wire necking Bond lifting, die lifting

Bond lifting, die lifting Thin film cracking, cratering beneath the bonds

Thin film cracking, cratering beneath the bonds

Corrosion due to ionic contaminants

Corrosion due to ionic contaminants Popcorning

Popcorning Increase in thermal resistance due to delamination

Increase in thermal resistance due to delamination